QED PERFORMANCE XT25

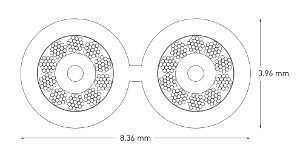

Pair of factory terminated acoustic speaker cables | 99.999% OFC copper | Conductor cross-section: 2.5 mm² | External dimensions: 3.96x8.36mm

Se effettui un ordine superiore a € 300 con due o più prodotti, la spedizione sarà gratuita. Le tempistiche stimate di spedizione sono indicate.

Paga in modo semplice e sicuro con Carta di credito, Contrassegno, AMEX, PayPal e Bonifico bancario. La tua privacy è garantita da connessioni sicure.

Tutti i prodotti sono coperti da Garanzia convenzionale di 2 anni. Risolviamo problemi di qualsiasi natura con professionalità e correttezza.

Solo tramite eMail dal Lunedì al Venerdì dalle ore 9:30 alle 15:00.

Pair of high quality acoustic loudspeaker cables with 99.999% OFC Copper conductors factory terminated with QED AirLoc Forté banana plugs

Available lengths selectable from drop-down menu.

The journey to XT25...

The QED loudspeaker cable story began in 1973, with the launch of the world's first specialised loudspeaker cables, QED 42 and 79 wire, now household names in the audio industry. Building on this legacy of long-standing British speaker cables, QED undertook an exhaustive programme of research into cable parameters that began in 1995 and continued in 2017 with the release of 'The Sound of Science', a 40-page white paper distilling the research published since 1973 by QED

These reports define the 'top down' design principles that most recently led to the development of the QED XT25 loudspeaker cable, the new class-leading standard in midrange and mid-range loudspeaker cables.

What are the features that make this cable so special?

X-Tube technology was first recognised in 2005 with the launch of the famous Silver Anniversary XT, the world's most popular mid-range cable, winning Hi-Fi Product of the Year three years in a row. These design principles are also appreciated by the award-winning XT40 and XT25 loudspeaker cable.

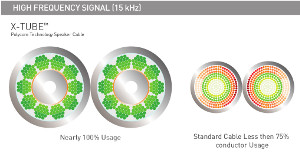

As frequency increases, electrons flow more and more towards the periphery of a conductor so that if the frequency is high enough, only a very thin layer (or skin) is used on the outside of the conductor. This 'skin depth' varies for different materials at a fixed frequency and in copper means that if a conductor has a cross-sectional area greater than 0.66 mm2, not all of this area is available for an analogue music signal to use. In SAXT, the problem of the 'skin' effect has been effectively eliminated by the use of X-Tube technology, which works by placing all conductor material around a central insulating rod. However, for a.c. signals, modifying the magnetic fields generated by the flow of eddy currents installed in neighbouring conductors forces the current to flow only in the areas furthest from the conductors carrying current in the same direction and vice versa

This 'proximity effect' has a negative influence on the current distribution in a loudspeaker cable, even if it uses X-Tube technology. With XT25, we address the proximity and skin effect by combining our existing Aircore and X-Tube technologies in a new X-Tube variant. By forming the conductors in a tubular shape with a hollow centre, current densities are maintained at higher frequencies because the electric field contributing to the skin effect acts towards the centre of the conductor from which the conducting material has been removed. At the same time, instead of using a braided structure, a ring of conductors is formed into separate bundles with only a loose electrical coupling, which is then twisted into a 90-mm arrangement so that no single conductor bundle remains inside or outside the cable (and thus falls prey to the proximity effect) for as long as it takes for it to become an audible problem. This geometry promotes a more coherent signal distribution for more accurate musical reproduction

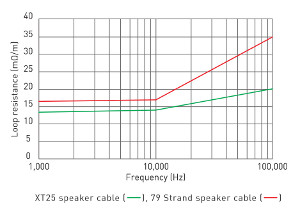

Low DC resistance

At QED we recognise that the low DC resistance of the loudspeaker cable is of paramount importance for high-fidelity signal transfer. This is because the loudspeaker presents a frequency-dependent load to the amplifier of which the cable forms a variable proportion. If the resistance is allowed to be too large, audible changes will be introduced to the frequency response characteristics of the loudspeaker that cannot be corrected by the amplifier's negative feedback circuit. In order to provide a marked improvement over similarly priced cables in our and our competitors' ranges without substantially increasing the size and flexibility of the cable, the cross-sectional area (CSA) of XT25 was expanded to 2.5 mm2 of 99.999 % oxygen-free copper. This immediately gives the new cable a low d.c. resistance and thus a more accurate musical delivery.

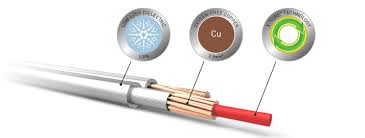

Low-loss dielectric

It is not generally appreciated that electrical signals move at the speed of light in a wire or do so through the medium of electromagnetic (EM) waveforms that exist within the dielectric surrounding the conductors and within the conductors themselves. The movement of electrons along the conductor simply facilitates the generation of the EM waveform as their 'drift speed' is only a few centimetres per second. It is therefore important to ensure that the dielectric material used to insulate and protect the central conductors of the loudspeaker cable is of a type that 'allows' the creation of EM waveforms without appreciable loss. Dielectric losses are directly proportional to the 'permittivity' of the material used and, as a measure of any material relative to that in vacuum, should be as close to unity as possible. Like its predecessors, XT25 uses a specially designed low-density polyethylene (LDPE) dielectric that at 1.69 has the lowest relative permittivity practically available.

Research on QED has shown that low-capacity cables are generally preferred in listening tests over high-capacity counterparts, and this is usually due to the fact that low-loss dielectrics are used. The use of LDPE and careful control of conductor spacing results in a cable with a very low capacitance per metre and a dissipation factor (loss tangent) of 0.0001 at 10 kHz

What is the result of all these techniques?

The graph below shows how the DC resistance of XT25 remains effectively unchanged across the entire audible frequency band when compared to a conventional cable of the same cross-sectional area. Combined with the sonic advantages of a low-loss dielectric, the improvements in current distribution place the new cable in a class well above cables with a less sophisticated geometry.

So, unless you have invested in XT25 with QED X-Tube technology, you may lose much of the performance of your expensive loudspeakers.

Convinced?

Make sure you get the most out of your new purchase by asking your dealer to install QED AirLoc Forté connectors designed to keep your XT25 sound as good as new for life.

What makes XT25 unique?

1. Award-winning heritage guaranteed All QED cables are designed using the top down principle. XT25 represents the main musical performance derived from our Supremus cable without money in a cheaper package. QED has won more What Hi-Fi? Awards than any other single brand and with XT25 this heritage is delivered at a reasonable price. Unlike most other manufacturers, QED offers an unlimited lifetime warranty, which means that if your cable fails to deliver its full potential over its lifetime, we will replace it free of charge.

2. X-Tube Technology .... but with a twist In loudspeaker cables, high-pitched sounds are forced to move towards the outside of the conductor and are therefore able to utilise less and less of the available cross-sectional area as the height increases. This is called the 'skin effect'. It means that for high frequencies the resistance of the cable appears to be much higher than for sounds with lower tones. Eddy currents in a conductor can influence the current flowing in an adjacent conductor so that currents flowing in the same direction move away from each other. This 'proximity effect' also increases resistance as frequency increases. These phenomena have a negative effect on the fidelity of the sound you hear. The XT25 variation of QED X-Tube technology solves these problems by creating a hollow tubular conductor geometry from bundles of individual conductors through which each frequency can pass with equal ease compared to traditional solid or flexible conductors.

3. Low-loss dielectric The music signals in a loudspeaker cable move back and forth many times per second. The insulating material used to separate the forward and return conductors from each other (the dielectric) must be charged and discharged each time. Not all the energy stored in the dielectric during each charge cycle is fully returned during each discharge cycle, which has a negative effect on the fidelity of the sound you hear. This is why at QED we use low-loss dielectric materials such as polyethylene (PE) or Teflon (PTFE) as an alternative to the cheaper PVC alternatives found in unbranded inferior cables.

4. 99.999% oxygen-free copper Speaker cables must have a large current-carrying capacity. If the electrical resistance of the cable is too great, part of the music signal will be lost, which will have a negative effect on the fidelity of the sound you hear. To prevent this from happening, we minimise the resistance of our speaker cables. We do this by using the largest cross-sectional area of copper within the size limits of each cable. To squeeze the last drop of performance out of the conductors, we make sure that there are no impurities in the copper that would defeat the purpose of making them so large. That is why we only use 99.999% oxygen-free copper.

5. Listen

Proprietary technology and trademark geometries plus our award-winning heritage combine to create audible sonic improvements over other loudspeaker cables.

- Cross-sectional area 2.5 mm2

- Wire gauge 14 AWG

- Jacket outer diameter 3.96 mm

- Circuit inductance 0.52 μH / m

- Circuit resistance 13.4 mΩ / m

- Capacitance 35.0 pF / m

- Dissipation factor @ 10 kHz 0.0001

- Conductors 10 x 19 / 0.13 mm

- Insulating LDPE jacket with 100% Mylar aluminium foil cover

- QED Airloc Forte banana plugs