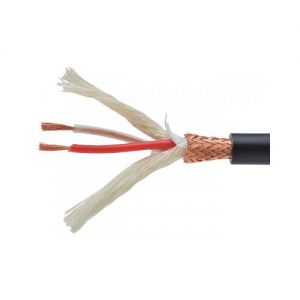

KLE INNOVATIONS COPPER HARMONY RCA SOCKET

Pair of solid pure copper panel RCAs | Thermoplastic polymer and glass fibre body

Se effettui un ordine superiore a € 300 con due o più prodotti, la spedizione sarà gratuita. Le tempistiche stimate di spedizione sono indicate.

Paga in modo semplice e sicuro con Carta di credito, Contrassegno, AMEX, PayPal e Bonifico bancario. La tua privacy è garantita da connessioni sicure.

Tutti i prodotti sono coperti da Garanzia convenzionale di 2 anni. Risolviamo problemi di qualsiasi natura con professionalità e correttezza.

Solo tramite eMail dal Lunedì al Venerdì dalle ore 9:30 alle 15:00.

Pair of panel RCAs with solid pure copper conductors and thermoplastic polymer and glass fibre body.Panel thickness from 1mm to 6mm

Identifying colours: white and red

The KLEI Harmony panel RCA connector is designed to fit a chassis plate/panel (e.g. preamplifier, amplifier, cdp, etc.) with a thickness of 1~4.5 mm (with washer) or up to 6.0 mm (without washer)

FEATURES

- Identification number: 2 located on the back of the connector

- Proprietary mathematical modelling is used to produce the Classic Harmony ground to indicate the pin relationship, parameters and determines the proprietary metallurgical processes that are used.

- Rate: >101% IACS, also >102% IACS

- The design of the Harmony RCA socket complements or mirrors the design of the Harmony Bullet plug.

- Excellent for digital, such as SPDIF, etc.

- Uses a standard M10 panel hole, M10 nut (thin), M10 washer and an extremely high temperature melting point polymer that tolerates the high temperature soldering required for high silver content soldering

- Increased conductivity. The calculations show a progression in percentage IACS, in the series. higher than that of the Classic Harmony socket

MOUNTING

- Mark the location of the Harmony RCA connector and drill or punch an M10 diameter hole (e.g. 10mm)

- Install/insert the Harmony RCA connector through the hole and install the nut and washer to secure it to the plate/panel, but do not over-tighten.

WELDING

- We recommend using a 60 watt soldering iron with a wide tip for rapid heat transfer. To aid heat conduction, be sure to tin the iron by melting a small amount of solder on the tip

- Tin the connector label and wire.

- Solder the earth conductor to the earth (-) tag and solder the signal conductor to the signal (+) tag, applying heat (and solder as required) to generate the solder flux. Once the solder has flowed over the connection, remove the heat (soldering iron).

MATERIAL: From the outset, KL has had an understanding of and sensitivity to electron/energy flow. His designs focus on signal integrity, elimination or mitigation of the causes of electron turbulence, especially eddy currents, capacitive reactance and micro-arc. A central theme in his designs was the choice of materials. He made the conscious decision to eliminate metal housings as standard on his connectors, as well as the universally used metal collars. Whether magnetic or not, the metals surrounding the conductor contribute to electron chaos and inhibit the smooth flow of the signal. KL uses highly heat-resistant and electrically inert polymers for both the housing and the collar. Not as a cost saving, but for better performance. In fact, the equipment required for these glass-impregnated polymer housings undoubtedly results in higher costs than for metal housings. These materials serve to improve signal integrity and reduce or eliminate known compromises to smooth electron flow

OPTIMAL MASS: Bigger, thicker and more massive does not mean better sound. Quite the contrary. A studied, optimised and in most cases minimalist approach to mass actually results in better sound and better electron/energy flow. KL's proprietary mathematical signal-to-ground formulas ensure an optimal architectural relationship between all metal complements and dielectrics used. The result is the control and avoidance of sound compromises caused by the skin effect. In addition, the reduction of EF and EMF interference. The control of these parameters guarantees a complete and extended frequency range, in which harmonics are transmitted intact from one component to another.

METALLURGY: This is of paramount importance; and something that has been central to KL's designs from the very beginning. KLEI is committed to implementing and using only conductors in its current Harmony RCA connectors that are more conductive than solid/pure copper and even solid/pure silver. KL's Harmony RCA connectors all have an IACS rating of 101% or higher and are breaking conceptual boundaries that were previously considered absolute. Much has happened since the days of the original Bullet Plug; and the metallurgy used in KLEI Harmony RCA connectors represents new knowledge that has arisen from research into forming and finishing processes, as well as metallurgical affinities and inherent crystal structures. Importantly, the signal and ground pins of the KLEI Harmony RCA connectors are harmoniously formed so that the metallurgical processes work together and not in opposition to each other, both electrically and mechanically.

ARCHITECTURE: The RCA Socketground collar/body, which in conventional designs surrounds the signal pin, acts as a conductor that transfers electrons/energy from multiple directions along its surfaces and surrounds the signal pin. It is subject to small, out-of-control turbulences called eddy currents. These turbulences are nothing more than chaos, exacerbated by the non-specific ground point in the design of RCA sockets, especially since an entire surface surrounding the centre pin forms the electrical ground. Capacitive reactance and micro-arc are additional artefacts of this architecture. The Harmony RCA socket design solves these problems and offers an elegant redesign of the RCA socket. Rather than surround the signal pin with a metal grounding collar/body, we opted for... The signal pin using a single-point contact/connection, similar to the star grounding used in high-end electronics.

- The Signal pin is positioned perpendicular to the Ground pin to ensure that EMF and inductive effects are minimal and negligible. In addition, the Signal and Ground pins are arranged and positioned to maintain and ensure a constant maximum distance from each other, which further enhances capacitive and inductive reactance effects and minimises EMF cross-talk effects that occur in all other RCA sockets. This allows significantly higher characteristic impedance than conventional RCA sockets and makes the Harmony RCA socket ideal for digital interconnects requiring RCA connectivity with 50, 75 or 110 ohm impedances and ultra-low jitter.

- The RCA socket design is the complement, or mirror image, of the Harmony (Bullet) plug design. In addition, the Harmony RCA socket and Harmony Bullet connection are designed to ground before the signal, but it is always recommended to turn off all components before connecting or disconnecting any electrical connection

- Total length: 28.5 mm, including welding label

- Maximum diameter: 16mm

- Panel/frame hole diameter: 10mm

- Panel/frame width/thickness: 1mm up to 4.5mm with washer

- Panel washer: 15mm diameter, 1.5mm wide, externally mounted

- Panel nut: M10, 12mm spanner, width 3.5mm, externally mounted

- Identification colour: white and red